Page 7 - Pump Brochure - Hi-Tech Compressor

P. 7

introducing:

dynamic Balancing

Vibration caused by mass imbalance in rotating

machinery is a critical engineering problem. The objective

of balancing is to reduce rotor vibration to a practical

minimum. Reducing rotor vibration generally increases

the service life of the rotating machinery.

Rotating machinery is commonly used in mechanical

systems, including industrial turbo-machinery and gas

turbine engines. Vibration caused by mass imbalance is

a common problem in rotating machinery. Imbalance

occurs if the principal axis of inertia of the rotor is not

coincident with its geometric axis. Higher speeds cause a

much greater centrifugal imbalance force and the current

trend of rotating equipment toward higher power density,

clearly leads to higher operational speeds. Therefore,

vibration control is essential in improving longer bearing

life; and ultimately reducing the number of unscheduled

shutdowns. A great cost savings for high speed pumps,

turbines, compressors and other turbo machinery used in

industries can be realized by removing the imbalance.

Balance is defined as “the process of adding or removing

mass in a plane or planes on a rotor in order to move the

center of gravity towards the axis of rotation”.

we inspect

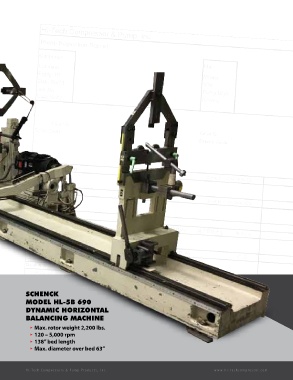

so you know what schenck

to expect model hl-5B 690

dynamic horizontal

Every pump that leaves Hi-Tech, Balancing machine

leaves with a detailed inspection

report, so you know the exact ► Max. rotor weight 2,200 lbs.

condition of that pump, and what ► 120 – 5,000 rpm

to expect from its performance. ► 138” bed length

► Max. diameter over bed 63”

H i - Te c h C o m p r e s s o r s & P u m p P r o d u c t s , I n c . w w w . h i - t e c h c o m p r e s s o r. c o m