Page 4 - Thermal Spray - Hi-Tech Compressor

P. 4

Sulzer Metco

2.4 Thermal Spray Coating Processes Sulzer Metco

2.4 Thermal Spray Coating Processes

There are several different processes used to apply a • Plasma spray and

• Plasma spray and

thermal sprayed coating. They are:

There are several different processes used to apply a • High velocity oxy-fuel spray (HVOF).

thermal sprayed coating. Th • High velocity oxy-fuel spray (HVOF).

• Conventional flame spray,ey are:

• Electric arc wire spray,

• Conventional flame spray, Details of these processes follow [ 2 ] .

• Electric arc wire spray, Details of these processes follow [ 2 ] .

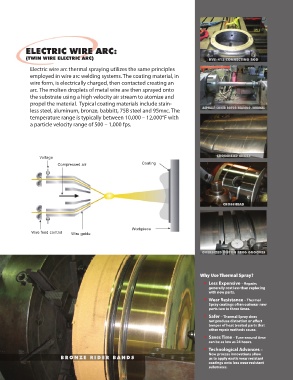

ELECTRIC WIRE ARC: FLAME SPRAY:

2.4.1

Conventional Flame Spray Process

(TWIN WIRE ELECTRIC ARC) KVS-412 CONNECTING ROD (OXY-ACETYLENE) Conventional Flame Spray Process

2.4.1

2.4.1.1 Wire Flame Spray Fuel gas Wire

2.4.1.1 Wire Flame Spray

Electric wire arc thermal spraying utilizes the same principles Flame spray, also known as oxy/ Fuel gas Wire Air cap

With the wire flame spray process, the

Air cap

wire spray material is melted in a

employed in wire arc welding systems. The coating material, in acetylene combustion spray is the Coating

With the wire flame spray process, the

wire spray material is melted in a

gaseous oxygen-fuel flame.

wire form, is electrically charged, then contacted creating an original thermal spray technique Coating

gaseous oxygen-fuel flame.

The fuel gas can be acetylene, propane

arc. The molten droplets of metal wire are then sprayed onto developed about 100 years ago.

or hydrogen.

The fuel gas can be acetylene, propane

the substrate using a high velocity air stream to atomize and It uses the basic principles of a

or hydrogen.

propel the material. Typical coating materials include stain- welding torch with the addition of

The wire is fed concentrically into the

flame, where it is melted and atomized

The wire is fed concentrically into the

less steel, aluminum, bronze, babbitt, 75B steel and 95mxc. The ASPHALT/COKER ROTOR BEARING JOURNAL a high velocity air stream to propel

by the addition of compressed air that

flame, where it is melted and atomized

temperature range is typically between 10,000 – 12,000°F with molten particles onto the substrate. Workpiece

also directs the melted material towards

by the addition of compressed air that

the workpiece surface.

also directs the melted material towards

a particle velocity range of 500 – 1,000 fps. The coating material can be either Oxygen Air passage Workpiece

Air passage

the workpiece surface.

wire or powder form. Often ame Oxygen Nozzle

Nozzle

spray coatings are fused after being Figure 4 a • Schematic diagram of the wire flame spray process

W I R E C O A T I N G

Figure 4 a • Schematic diagram of the wire flame spray process

applied to enhance bond strengths

and coating density. The gas tem- Powder

2.4.1.2 Powder Flame Spray

Voltage CROSSHEAD SHOES perature range is typically between Fuel gas Powder

2.4.1.2 Powder Flame Spray

This coating process is based on the

Compressed air Coating 4,600 – 5,200 °F with a particle Fuel gas Nozzle Coating

same operational principle as the wire

This coating process is based on the

Nozzle

flame spray process, with the difference

same operational principle as the wire Coating

that the coating material is a spray pow-

flame spray process, with the difference

velocity range of 300 – 800 fps.

der. Thus, a larger selection of spray

that the coating material is a spray pow-

materials is available, as not all spray

der. Thus, a larger selection of spray

materials can be manufactured in wire

materials is available, as not all spray

form.

materials can be manufactured in wire

form.

CROSSHEAD

Oxygen

Workpiece

Oxygen

Figure 4b • Schematic diagram of the powder flame spray process

Workpiece

Figure 4b • Schematic diagram of the powder flame spray process

Workpiece P O W D E R C O A T I N G

Wire feed control Wire guide

OVERSIZED PISTON RING GROOVES An Introduction to Thermal Spray 8 / 24

An Introduction to Thermal Spray 8 / 24

C O A T I N G E N E R G Y R A N G E B Y T Y P E T E M P E R A T U R E V S T H I C K N E S S

Why Use Thermal Spray?

► Less Expensive – Repairs 1000

generally cost less than replacing

with new parts. 800

► Wear Resistance – Thermal

Spray coatings often outwear new

parts two to three times. 600

► Safer – Thermal Spray does Thermal Energy Substrate Temperature [°C]

not produce distortion or a ect 400

temper of heat treated parts that

other repair methods cause. 200

► Saves Time – Turn-around time

can be as low as 24 hours.

0

0.1 1 10 100 1000 10000

► Technological Advances – Kinetic Energy

New process innovations allow Coating Thickness [μm]

B R O N Z E R I D E R B A N D S us to apply exotic wear resistant

coatings onto less wear resistant

substrates.

H i - Te c h C o m p r e s s o r s & P u m p P r o d u c t s , I n c . ( 8 0 0 ) 5 8 1 - 6 0 4 5